©Endress+Hauser

Successor

Accurate single-tube flowmeter for lowest flow rates with a compact, easily accessible transmitter

Read more

Accurate single-tube flowmeter for lowest flow rates, as remote version with up to 4 I/Os

Read more

Simple products

Easy to select, install and operate

Technical excellence

Simplicity

Standard products

Reliable, robust and low-maintenance

Technical excellence

Simplicity

High-end products

Highly functional and convenient

Technical excellence

Simplicity

Specialized products

Designed for demanding applications

Technical excellence

Simplicity

FLEX selections

Technical excellence

Simplicity

Fundamental selection

Meet your basic measurement needs

Technical excellence

Simplicity

Lean selection

Handle your core processes easily

Technical excellence

Simplicity

Extended selection

Optimize your processes with innovative technologies

Technical excellence

Simplicity

Xpert selection

Master your most challenging applications

Technical excellence

Simplicity

Product headline

The single‐tube flowmeter for smallest quantities with custody transfer functionality. Measuring accurately smallest quantities of liquids and gases for continuous process control.

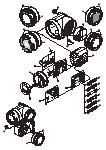

Sensor features

Highest process safety – self‐drainable measuring tube design. Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in/outlet run needs. Nominal diameter: DN 2 to 4 (¹⁄₁₂ to ¹⁄₈"). Process pressure up to 400 bar (5800 psi).

Transmitter features

Quality – designed for custody transfer; featuring worldwide recognized metrological approvals. Flexible data transfer options – numerous communication types. Automatic recovery of data for servicing. 4‐line backlit display with touch control. Device in compact or remote version.

Wetted materials

Measuring tube: 1.4539 (904L); Alloy C22, 2.4602 (UNS N06022)

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density

Max. measurement error

Mass flow (liquid): ±0.1 %

Measuring range

0 to 450 kg/h (0 to 16.5 lb/min)

Max. process pressure

PN 40, Class 300, 20K, 400 bar (5800 psi)

Medium temperature range

–50 to +200 °C (–58 to +392 °F)

Ambient temperature range

Standard: –20 to +60 °C (–4 to +140 °F)

Sensor housing material

1.4301 (304), corrosion resistant

Transmitter housing material

Powder‐coated die‐cast aluminium

Degree of protection

IP67, type 4X enclosure. Remote transmitter: IP67, type 4X enclosure

Display/Operation

4‐line backlit display with touch control

Outputs

4 modular outputs:

Power supply

DC 16 to 62 V

Hazardous area approvals

ATEX, IECEx, FM, CSA, NEPSI, EAC

Other approvals and certificates

3.1 material, calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR, custody transfer, CRN, 3-A

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR

Pressure approvals and certificates

Hygienic approvals and certificates

Product headline

The single‐tube flowmeter for smallest quantities with custody transfer functionality. Measuring accurately smallest quantities of liquids and gases for continuous process control.

Sensor features

Highest process safety – self‐drainable measuring tube design. Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in/outlet run needs. Nominal diameter: DN 2 to 4 (¹⁄₁₂ to ¹⁄₈"). Process pressure up to 400 bar (5800 psi).

Transmitter features

Quality – designed for custody transfer; featuring worldwide recognized metrological approvals. Flexible data transfer options – numerous communication types. Automatic recovery of data for servicing. 4‐line backlit display with touch control. Device in compact or remote version.

Wetted materials

Measuring tube: 1.4539 (904L); Alloy C22, 2.4602 (UNS N06022)

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density

Max. measurement error

Mass flow (liquid): ±0.1 %

Measuring range

0 to 450 kg/h (0 to 16.5 lb/min)

Max. process pressure

PN 40, Class 300, 20K, 400 bar (5800 psi)

Medium temperature range

–50 to +200 °C (–58 to +392 °F)

Ambient temperature range

Standard: –20 to +60 °C (–4 to +140 °F)

Sensor housing material

1.4301 (304), corrosion resistant

Transmitter housing material

Powder‐coated die‐cast aluminium

Degree of protection

IP67, type 4X enclosure. Remote transmitter: IP67, type 4X enclosure

Display/Operation

4‐line backlit display with touch control

Outputs

4 modular outputs:

Power supply

DC 16 to 62 V

Hazardous area approvals

ATEX, IECEx, FM, CSA, NEPSI

Other approvals and certificates

3.1 material, calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR, custody transfer, CRN, 3-A

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR

Pressure approvals and certificates

Hygienic approvals and certificates

Characteristic / Application

Coriolis mass flowmeter for custody transfer application.

Process temperature

-50...+200°C

Process pressure

PN 16...400

Wetted parts

904L/1.4539

Output

4...20mA

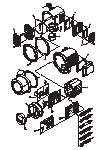

Product headline

The single‐tube flowmeter for smallest quantities with custody transfer functionality. Measuring accurately smallest quantities of liquids and gases for continuous process control.

Sensor features

Highest process safety – self‐drainable measuring tube design. Fewer process measuring points – multivariable measurement (flow, density, temperature). Space‐saving installation – no in/outlet run needs. Nominal diameter: DN 2 to 4 (¹⁄₁₂ to ¹⁄₈"). Process pressure up to 400 bar (5800 psi).

Transmitter features

Quality – designed for custody transfer; featuring worldwide recognized metrological approvals. Flexible data transfer options – numerous communication types. Automatic recovery of data for servicing. 4‐line backlit display with touch control. Device in compact or remote version.

Wetted materials

Measuring tube: 1.4539 (904L); Alloy C22, 2.4602 (UNS N06022)

Measured variables

Mass flow, density, temperature, volume flow, corrected volume flow, reference density

Max. measurement error

Mass flow (liquid): ±0.1 %

Measuring range

0 to 450 kg/h (0 to 16.5 lb/min)

Max. process pressure

PN 40, Class 300, 20K, 400 bar (5800 psi)

Medium temperature range

–50 to +200 °C (–58 to +392 °F)

Ambient temperature range

Standard: –20 to +60 °C (–4 to +140 °F)

Sensor housing material

1.4301 (304), corrosion resistant

Transmitter housing material

Powder‐coated die‐cast aluminium

Degree of protection

IP67, type 4X enclosure. Remote transmitter: IP67, type 4X enclosure

Display/Operation

4‐line backlit display with touch control

Outputs

4 modular outputs:

Power supply

DC 16 to 62 V

Hazardous area approvals

ATEX, IECEx, FM, CSA, NEPSI, EAC

Metrological approvals and certificates

Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR Custody transfer approvals: MI-002 (gas), MI-005 (liquid) , PTB 7.251 (gas)

Pressure approvals and certificates

Hygienic approvals and certificates

76 documents

Proline Promass 84A

Technical Information

Coriolis flowmeter

EN

German French Italian

06/02/2015

15/10/2012

01/11/2009

01/09/2008

01/09/2007

Language:

English

Version:

06/02/2015

File size:

846 KB

File name:

TI00068DEN_1415.pdf

Proline Promass 84

HART

Description of Device

Functions

Coriolis Mass Flow Measuring System for Custody Transfer. Additional

EN

Czech German French Italian Polish Russian

01/09/2008

01/12/2006

01/03/2005

Language:

English

Version:

01/09/2008

File size:

1.4 MB

File name:

BA110DEN_0908.pdf

Proline Promass 84

Modbus RS485

Operating Instructions

Coriolis Mass Flow Measuring System for Custody Transfer. The

EN

Bulgarian German Italian Russian

15/10/2012

31/12/2011

08/06/2010

01/11/2008

01/12/2006

Language:

English

Version:

15/10/2012

File size:

2.4 MB

File name:

BA00129DEN_1412.pdf

Proline Promass 84

HART

Operating Instructions

Coriolis Mass Flow Measuring System for Custody Transfer. The

EN

Bulgarian German French Italian Polish Russian

15/10/2012

31/12/2011

01/11/2008

01/12/2006

01/03/2005

Language:

English

Version:

15/10/2012

File size:

2.2 MB

File name:

BA00109DEN_1412.pdf

Proline Promass 84

MODBUS RS485

Description of

Device Functions

Coriolis Mass Flow Measuring System for Custody Transfer. Additional

EN

German Italian

01/11/2008

01/12/2006

Language:

English

Version:

01/11/2008

File size:

1.5 MB

File name:

BA130DEN_1108.pdf

Proline Promass 84

Brief Operating Instructions

Coriolis Mass Flow Measuring System

EN

Czech German Spanish Estonian French Italian Chinese

15/10/2012

31/12/2011

01/07/2007

Language:

English

Version:

15/10/2012

File size:

671.5 KB

File name:

KA00025DEN_1412.pdf

Replacing amplifier board

Installation Instructions

Promag 50, 51, 53, 55, Promass 40, 80, 83, 84, Cubemass DCI 8CN, CNGmass

EN

German

15/11/2018

05/08/2014

Language:

English

Version:

15/11/2018

File size:

393.9 KB

File name:

EA00064DA2_1518.pdf

Replacing Power supply and display

Installation Instructions

Promag 50, 51, 53, 55, Promass 40, 80, 83, 84, 8ME, Cubemass DCI 8CN,

EN

German

15/11/2018

18/11/2011

Language:

English

Version:

15/11/2018

File size:

455.1 KB

File name:

EA00063DA2_1518.pdf

Replacing T-DAT

Installation Instructions

Promag 23, 53, 55, Promass 83, 84, 8WF, 8ME, Cubemass DCI 8CN, CNGmass

EN

German

15/11/2018

21/11/2011

Language:

English

Version:

15/11/2018

File size:

481.6 KB

File name:

EA00072DA2_1418.pdf

Replacing amplifier board for harsh environment (HE)

Installation Instructions

Promag 50, 53, 55, Promass 80, 83, 84, Cubemass DCI 8CN, CNGmass DCI 8DF

EN

German

15/11/2018

10/10/2014

05/08/2014

Language:

English

Version:

15/11/2018

File size:

379.4 KB

File name:

EA00067DA2_1518.pdf

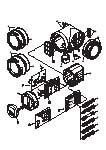

Search spare parts by number in drawing

60 spare parts & accessories

60 spare parts & accessories

60 spare parts & accessories

Kit power s.b. 40/8X/65 220V REx000

Drawing number

Order code

F

50098557

Kit p.s.b.40/8X 220V REx000 HE

Drawing number

Order code

F

71039431

Kit p.s.b.40/8X 220V REx000 HE

Drawing number

Order code

F

71039431

Kit power s.b. 40/8X/65 220V REx120 Ex

Drawing number

Order code

F

50098558

Kit p.s.b.8X 220V REx120 HE Ex

Drawing number

Order code

F

71039432

Kit P.s.b. 40/8X/65 24V REx000

Drawing number

Order code

F

50098565

Kit p.s.b.8X 24V REx000 HE

Drawing number

Order code

F

71039434

Kit P.s.b. 40/8X/65 24V REx120 Ex

Drawing number

Order code

F

50098566

Kit P.s.b. 8X 24V REx120 HE Ex

Drawing number

Order code

F

71039436

Kit 10 fuses 250 VAC T800 MA

Drawing number

Order code

7

50094002

Kit 10 fuses 250 VAC T 2A00

Drawing number

Order code

7

50094003

Kit meas. amplifier Pmass 84 CN EX

Drawing number

Order code

B

50108694

Kit meas. amplifier 84 CN HE EX

Drawing number

Order code

B

71039416

Kit meas. amplifier Pmass 84 WEA EX

Drawing number

Order code

B

50108695

Kit meas. amplifier 84 WEA HE EX

Drawing number

Order code

B

71039413

Kit meas. amplifier Pmass 84 EES EX

Drawing number

Order code

B

50108696

Kit meas. amplifier 84 EES HE EX

Drawing number

Order code

B

71039414

Kit meas. amplifier Pmass 84 SEA EX

Drawing number

Order code

B

50108697

Kit meas. amplifier 84 SEA HE EX

Drawing number

Order code

B

71039415

Kit commodul Iout passive/Frequency Exi

Drawing number

Order code

C

50098302

Kit I/O Iout passive/Frequency HE Exi

Drawing number

Order code

C

71039479

Kit commodul Iout active/Frequency Exi

Drawing number

Order code

C

50098303

Kit I/O Iout active/Frequency HE Exi

Drawing number

Order code

C

71039478

Kit Com ModbusRS485+stat.In 2Interf.Ex

Drawing number

Order code

D

71021743

Kit I/O Modb.RS485+Stat.In 2Interf.HE EX

Drawing number

Order code

D

71039485

Kit Commodul current out 3 Interface Ex

Drawing number

Order code

D

50096833

Kit I/O current out 3 Interface HE EX

Drawing number

Order code

D

71039477

Drawing number

Order code

2

50096834

Kit Sub PCB current out HE

Drawing number

Order code

2

71039487

Drawing number

Order code

5

50096836

Drawing number

Order code

5

50096836

Drawing number

Order code

5

71039491

Drawing number

Order code

5

71039491

Drawing number

Order code

4

50096837

Kit Sub PCB Status input HE

Drawing number

Order code

4

71039492

Kit Sub PCB 84/8CN/8DF frequency out

Drawing number

Order code

31

50108692

Kit Sub PCB 84/8CN/8DF frequency out

Drawing number

Order code

31

50108692

Kit Sub PCB 84/8CN/8DF frequency out HE

Drawing number

Order code

31

71039490

Kit Sub PCB 84/8CN/8DF frequency out HE

Drawing number

Order code

31

71039490

Kit display modul Wall enclosure

Drawing number

Order code

J

50096755

Drawing number

Order code

E

50096754

Kit Bus/connec.b.5X/40/8X/65 field hous.

Drawing number

Order code

G

50094016

Kit Bus PCB/PCB carr.5X/8X/9X/65 wall

Drawing number

Order code

21

50094017

Kit Bus/connec.b.5X/8X SS-housing

Drawing number

Order code

H

50099099

Kit connec. board In/Output Wall encl

Drawing number

Order code

18

50094014

Kit connec. board PMASS8X wall enclo

Drawing number

Order code

19

50098637

Kit connec. board 8X wall enclosur HE

Drawing number

Order code

19

71039493

Kit connection board 8X FS

Drawing number

Order code

A

50098705

Kit connection board 8X FS HE

Drawing number

Order code

A

71039494

Kit connection board 8X FS Ex

Drawing number

Order code

A

50098706

Kit connection board 8X FS HE EX

Drawing number

Order code

A

71039495

Kit Termin.Block field hous. 5X/8X/40/65

Drawing number

Order code

29

50108139

Kit Termin.Block Wall encl. 5X/8X/9X/65

Drawing number

Order code

30

50108140

Kit T-DAT Transmitter Data Chip

Drawing number

Order code

1

50094004

Kit S-Dat Promass 84/8CN/8DF programmed

Drawing number

Order code

S

71003953

Kit Cover 5X/40/8X/65 with window

Drawing number

Order code

8

50094026

Kit Cover 5X/40/8X/93/65 with window Exd

Drawing number

Order code

32

50094027

Kit Cover 5X/40/8X/65 version blind

Drawing number

Order code

9

50094028

Kit Cover 5X/40/8X/93/65 vers. blind Exd

Drawing number

Order code

33

50094029

Kit Cover Connection terminal

Drawing number

Order code

10

50094038

Kit Cover Connection terminal

Drawing number

Order code

10

50094038

Kit Cover 5X/40/8X/93/65 Conn.termi.Exe

Drawing number

Order code

34

50094039

Kit Cover 5X/40/8X/93/65 Conn.termi.Exd

Drawing number

Order code

35

50094040

Kit Cover 5X/8X with window SS-housing

Drawing number

Order code

17

50099100

Kit 10 cable glands M20x1,5

Drawing number

Order code

15

50096840

Kit 10 cable glands M20x1.5 Ex

Drawing number

Order code

15

50098036

Kit 10 cable glands M20x1.5 Ex

Drawing number

Order code

15

50098036

Kit 10 cable glands M20x1.5 Ex

Drawing number

Order code

15

50098036

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Drawing number

Order code

15

50098041

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Drawing number

Order code

15

50098041

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Drawing number

Order code

15

50098041

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Drawing number

Order code

15

50098041

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Drawing number

Order code

15

50098042

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Drawing number

Order code

15

50098042

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Drawing number

Order code

15

50098042

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Drawing number

Order code

15

50098042

Kit Circuit board cpl field/SS-housing

Drawing number

Order code

12

50096839

Kit Bushing to field/SS-housing

Drawing number

Order code

14

50099102

Kit Terminal protective Cover Ex

Drawing number

Order code

36

71008445

Kit Ground terminal / Cover clamp

Drawing number

Order code

13

50096841

Kit 2 Screening sheet wall enclo.

Kit 2 Screening sheet field housing

Kit Seal cover to Wall enclosure

Drawing number

Order code

20

50094041

Kit 10 Seal cover to field housing

Drawing number

Order code

11

50094050

Kit housing gaskets SS-Field housing

Drawing number

Order code

16

50099101

Kit Part 8X Stainless housing comp.

Drawing number

Order code

23

50098701

Kit Part 8X fieldhousing compact

Drawing number

Order code

22

50098702

Drawing number

Order code

24

50098704

Kit cable Promass remote version 10m

Drawing number

Order code

28

50093554

Kit cable Promass remote version 20m

Drawing number

Order code

28

50093573

Kit cable PROMASS remote version 10m Ex

Drawing number

Order code

28

50098567

Kit cable PROMASS remote version 20m Ex

Drawing number

Order code

28

50098568

Kit Screw sealing 84/8DF/8FE/8FF

We value your privacy

We use cookies to enhance your browsing experience, collect statistics to optimize site functionality, and deliver tailored advertisements or content.

By selecting "Accept all", you consent to our use of cookies.cookie policy .

Customize

Accept only essential

Accept all