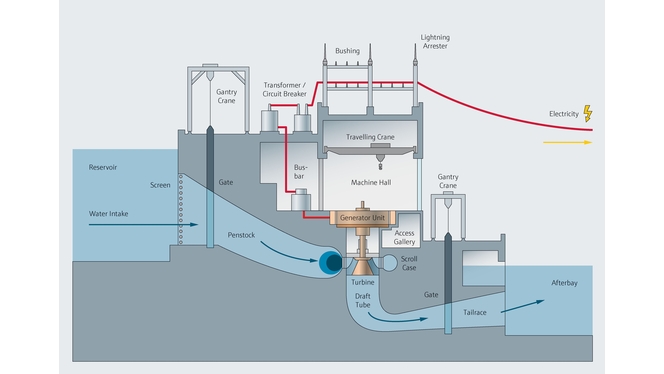

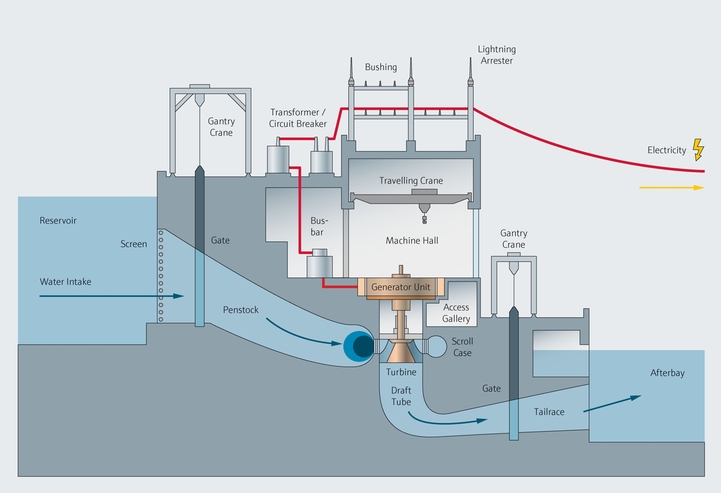

Hydroelectric and pumped storage power plants are able to store and deliver renewable energy on demand, need relatively little maintenance and have low running costs. However, they can be costly to build and vulnerable to natural events and equipment failure caused by high relative humidity, water that can be acidic or contain bacteria, sand or debris. Endress+Hauser offers the planning insight, reliable equipment and accurate instrumentation vital for hydroelectric plant safety.

Key facts

200 years

is the typical lifespan of a hydroelectric plant. Hydropower is the largest renewable source for electricity generation globally. It is an abundant, low cost source of power, despite high upfront building costs.

Turbine, generator and shaft temperature monitoring

Accurate temperature measurement is essential to the effective operation of any hydroelectric plant. Hot spots in the turbine bearings, generator bearings, guide- and thrust bearings must be rapidly identified to prevent energy loss through increased friction, and to protect against equipment damage and failure.

Our expertise in the field

Endress+Hauser’s vibration resistant Pt 100 temperature sensor range, including the iTHERM® StrongSens RTD, provides rapid, accurate temperature monitoring in demanding environments such as hydroelectric power plants (HPP).

- Install with ease thanks to modular and compact designs

- Monitor seamlessly with common communication protocol transmitters

- Reduce maintenance and downtime with reliable, durable, vibration-resistant Omnigrad temperature sensors

Turbine speed control & brake system monitoring

Measurement of levels in the governor tank / hydraulic oil storage tank, and of oil pressure, are vital to ensure the turbine speed and break control systems are functioning correctly, and wear is minimized.

Our expertise in the field

Endress+Hauser guided wave radar (GWR), capacitance level measurement technology and differential pressure level transmitters enable accurate governor tank monitoring for optimal turbine control and minimized system wear.

- Monitor the oil level in the governor tank with Levelflex FMP51 to ensure correct performance of the whole system

- Well known reliable (DP) level measurement using Deltabar S PMD75 in case of stable density

- Rely on safe operations regardless of tank geometry with our Liquicap product range

Temperature monitoring in high voltage area

Elevated ambient temperatures in power conversion and transmission areas can increase fire risks due to electric arcing. Constant temperature monitoring of such areas, combined with fire alarms, enhance plant safety.

Our expertise in the field

Endress+Hauser’s ambient RTD temperature sensor TST434, in combination with the latest state-of-the-art transmitters, has been designed specifically for use in such conditions.

- Monitor the ambient temperature in the bus-bar to avoid the risk of having both high voltage and high temperature

- Fulfill electromagnetic compatibility (EMC) in accordance with all the relevant requirements

- Benefit from high galvanic isolation and integrated Bluetooth® interface for remote operation via mobile devices

Sump water level measurement for drainage pump operation

Water-level, flood and evacuation alarms are essential for the safe operation of any hydroelectric plant. Any failure in the level measurement system that controls drainage pumps could have catastrophic consequences. Mechanical systems that incorporate floats or conductivity level measurements can be vulnerable to high humidity and corrosion, increasing the failure risk.

Our expertise in the field

Endress+Hauser’s ultrasonic, free space radar and hydrostatic level devices provide a reliable alternative to mechanical devices for level monitoring.

- Avoid equipment failure risks linked to humidity and corrosion

- Enhance plant safety with reliable level monitoring

- Implement flood protection schemes to automatically close intake gates or hilltop valves and keep turbines operating

Surge tank level measurement

The primary purpose of a surge tank is to control pressure variations due to rapid changes in water velocity. Measurement is needed to reduce water pressure surges that could damage the turbine or lead to increased stress. This ensures continuous energy production. Elevated ambient temperatures in high-voltage areas can increase fire risks due to electric arcing. Constant temperature monitoring of such areas, combined with fire alarms, enhance plant safety.

Our expertise in the field

Endress+Hauser experts will advise upon the best-fit solution for each crucial checkpoint to ensure surge tank protection and optimal operation, including options for independent power supply and wireless signal transmission.

- Install robust overload-resistant high purity ceramic sensors for reliable level control

- Benefit from non-contact free space radar with small beam angle for reliable level indication

- Limit values can be set and monitored for safety and operation purposes

Control valve position monitoring

Traditionally, differential pressure impulse lines or capillary dp-systems are used to monitor the valve position. Impulse lines are often blocked by impurities, but also water hammer/surges that can occur during start-up or shut-down of hydroelectric power plants affect this essential measurement for safe turbine operation (Francis, Kaplan, Pelton, etc.). In addition, the surge tank helps to relieve the pressure on the pipe.

Our expertise in the field

Endress+Hauser’s solution is the Deltabar FMD71, an electronic differential pressure measuring system, which is unaffected by impurities in the impulse lines, and is not affected by water hammer/surges or even temperature changes compared to dp-transmitters with oil-filled capillaries.

- Measures efficiently – issues of traditional differential pressure measurements with wet legs and diaphragm seals are eliminated

- Measures accurately – unaffected by water hammer/surges or temperature changes

- No compromises on installation position – just a simple electrical cable between the sensors and the transmitter

- Performance without worries in EMC fields

Benefits

Our highly trained services and sales staff partner with you to assess the potential to be gained by high-end measurement and automation to improve safety, efficiency and minimize downtime. Our project management and engineering staff accompany plant improvement from the outset – with experience and skills that go beyond instrumentation.

Key facts

> 10

years of experience in hydroelectric power projects, including project engineering for over 14500 MW of installed capacity

Key facts

One-stop

shop supplier. We deliver the most complete instrumentation portfolio along with local service and project management

How we can help

Endress+Hauser’s broad equipment and instrumentation portfolio and the profound power knowhow of our network, comprising engineering, sales and service staff, together enable hydroelectric power plant operators to safely maximize the potential of their facility throughout the operational lifecycle.

- Standardized technology and equipment for ease of integration

- Modernization experience for plant optimization

- Process automation for efficient operation

- Peak performance through efficiency and functionality