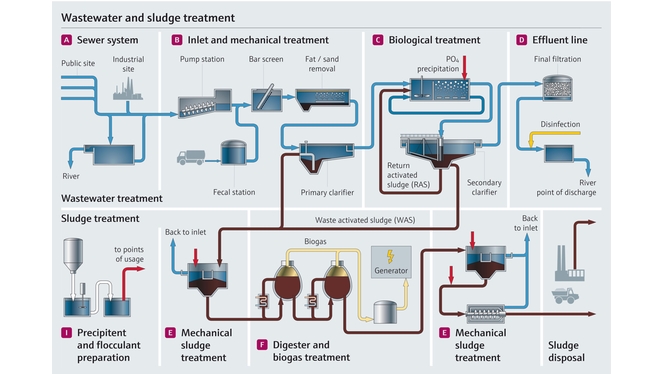

Industrial wastewater treatment is an inevitable challenge for many plant operators, with wastewater a byproduct of multiple industrial processes. Reusing wastewater in secondary capacities can bring efficiencies. When this is not possible discharge to a sewer or nature is the only option. Yet strict regulations for human and environmental safety make treatment of wastewater for discharge a costly and complex task. Our industrial wastewater treatment portfolio can ensure optimal processes.

Key facts

16%

of the global freshwater withdrawals

end up as industrial wastewater. Only 3% are actually consumed during the production processes.

Learn more about industrial wastewater treatment

Wastewater reuse

Wastewater reuse or recycling offers the dual benefits of lowering water intake and minimizing wastewater discharge costs. However, for wastewater to be recycled safely as industrial water it must be treated according to its future use, involving processes such as flotation, sedimentation and filtering.

Our expertise in the field

The Endress+Hauser portfolio enables the accurate monitoring and control of inlet pressure, quality and flow, vital to preventing damage to wastewater filters.

- Precise pressure control using our smart pressure transmitter Cerabar PM51B

- Discover our wastewater monitoring panels

- Reliable flow measurement at constant accuracy with 0 x DN inlet run with Proline Promag W 400

.jpg)

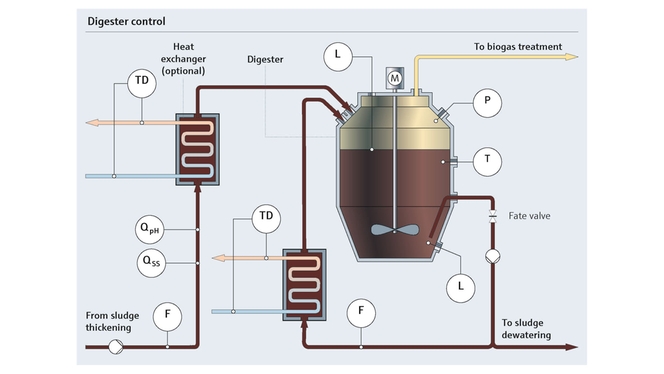

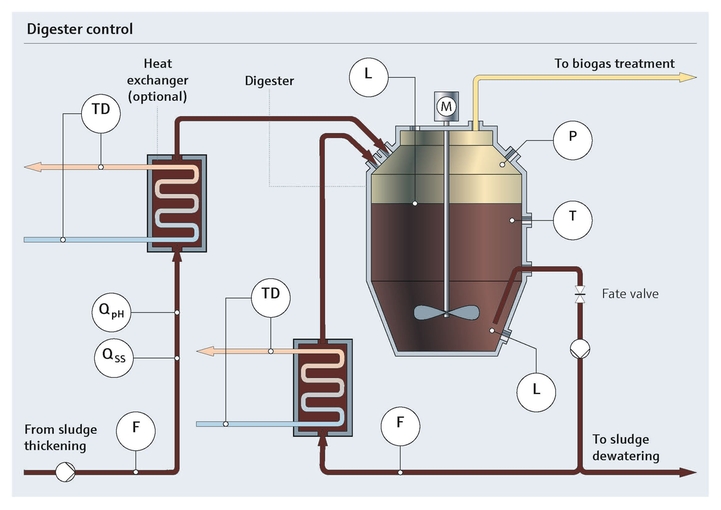

Anaerobic digestion

An efficient pre-treatment process for wastewater with a high Chemical Oxygen Demand (COD), such as from the pulp & paper industries, anaerobic digestion converts a proportion of organic load to biogas. Managing anaerobic digestion effectively necessitates accurate monitoring of multiple parameters throughout the process.

Our expertise in the field

Endress+Hauser offers a complete range of monitoring technologies for total anaerobic digestion process control and optimization, including:

- Robust temperature measuring with TR15 modular RTD thermometer

- Monitoring the inlet load level with hydrostatic sensor Deltapilot FMB50

- Better process overview Memosens sensor CPS16E which simultaneously measures pH, ORP and rH values (in rH mode)

- Monitoring biogas production with Proline Prosonic Flow B 200

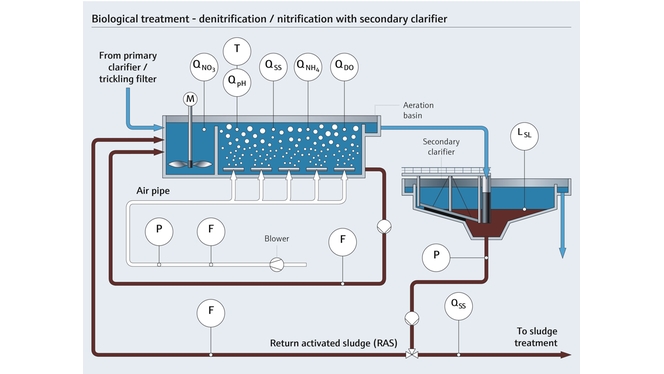

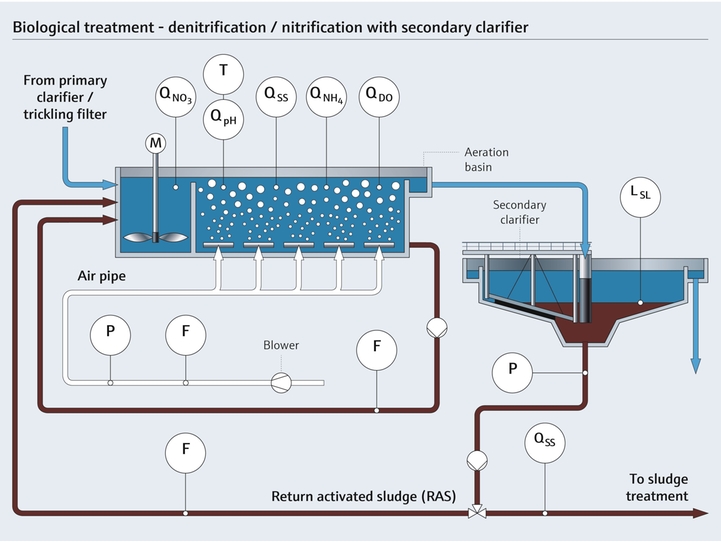

Biological treatment

Often following anaerobic digestion, wastewater with high organic load, such as from the food industry, will be treated biologically to reduce organic content. Ensuring that the right conditions exist to enable biological action is the main challenge with the biological treatment approach, and accurate monitoring of parameters such as ammonium, nitrate and oxygen levels is key.

Our expertise in the field

Endress+Hauser offers an extensive range of highly adaptable analyzers and sensors enabling accurate monitoring of a multitude of parameters in biological treatment:

- Ammonium analyzer Liquiline System CA80AM, colorimetric system for online monitoring of water and wastewater treatment

- Turbimax CUS51D Memosens sensor for suspended solids and turbidity measurement

- Digital oxygen sensor Memosens COS51E for ion level detection and monitoring

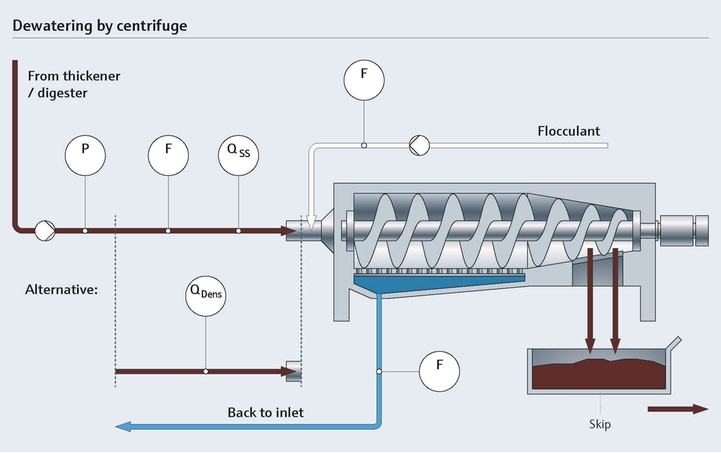

Sludge treatment

Both costly and complex, sludge treatment involves processes such as thickening or dewatering and the efficiency of both depends upon accurate monitoring of parameters such as flow, suspended solids and density to ensure optimal use of additives and conditioners.

Our expertise in the field

Offering high performance flow meters to measure all essential parameters, the Endress+Hauser portfolio optimizes chemical dosing in sludge disposal:

- Optimal flow control with electromagnetic flowmeter Proline Promag W 400

- Measuring density of dark sludge with a broad portfolio of Coriolis mass flowmeter

Benefits

Thanks to more of 60 years of experience that we have gained by working together with our customers in the water and wastewater industry, we have developed a broad portfolio of measuring technologies, automation solutions and service offerings that match the challenges of our customers. We understand the specific challenges of optimizing costs on the one hand and ensuring effluent quality to comply with environmental laws.

Key facts

30%

of the energy costs spent on aeration can be saved by controlling the aeration more accurately

Key facts

20%

potential cost savings on conditioner chemicals for sludge treatment

Key facts

250,000

digital analytic sensors installed worldwide

How we can help

Offering a complete portfolio of monitoring and analysis technologies, Endress+Hauser enables its customers to treat industrial wastewater more efficiently and with enhanced compliance, optimizing processes such as:

- Wastewater reuse

- Anaerobic digestion

- Biological treatment

- Sludge disposal